14 Feb

In recent years, warehouses have evolved from simple storage spaces into highly sophisticated centers of operation. The integration of smart software and AI-driven technologies has completely transformed how warehouses function, making them more efficient and smarter than ever before. This article will explore how smart software is revolutionizing warehouses, driving supply chain success, and pushing businesses toward operational excellence.

- What Makes Warehouses Smarter?

- How Does Smart Software Transform Your Business?

- Can AI Be the Key to Supply Chain Success?

- What Role Does Automation Play in Modern Warehouses?

- How Does AI Impact Inventory Management?

- How Does Data-Driven Decision Making Lead to Success?

- Conclusion: Is the Future of Warehousing Here to Stay?

What Makes Warehouses Smarter?

Modern warehouses are no longer just places where goods are stored. Thanks to cutting-edge smart software systems, they now act as the backbone of efficient logistics operations. These technologies enable warehouses to perform tasks faster, with fewer errors, and with enhanced visibility. From inventory management to order fulfillment, every step can now be automated or optimized. What makes this possible? The answer lies in the incredible capabilities of smart software, powered by artificial intelligence (AI).

AI technology helps automate tasks that were traditionally manual and error-prone, such as sorting and tracking products. Using advanced algorithms, smart software ensures accurate inventory levels, helping warehouse managers avoid overstocking or stockouts. Moreover, AI-driven systems can predict demand trends and optimize stock levels accordingly, ensuring that businesses can keep up with fluctuating customer needs without the burden of excess inventory.

How Does Smart Software Transform Your Business?

The implementation of smart software in warehouses offers a multitude of benefits for businesses across various industries. But how exactly does it transform your operations? Let’s break it down:

- Efficiency Gains: With automation taking over routine tasks like sorting, picking, and packing, employees can focus on more strategic activities. This leads to a more productive workforce and faster order processing times.

- Cost Savings: By reducing errors, improving inventory management, and optimizing labor, businesses save on operational costs. These savings can be reinvested in other areas, such as marketing, product development, or customer experience improvements.

- Improved Customer Satisfaction: Faster delivery times and fewer mistakes in order fulfillment lead to happier customers. In turn, this helps build loyalty and strengthens your brand reputation.

- Enhanced Data Analytics: The data collected by smart software provides insights into every aspect of the warehouse’s operation. Businesses can use this information to make better decisions, reduce bottlenecks, and improve overall performance.

Can AI Be the Key to Supply Chain Success?

Supply chain management is a complex process that requires precision and coordination. So, what role does AI play in ensuring supply chain success? AI technologies are now embedded throughout the supply chain, not just in warehouses, and they work together to optimize the entire process. From demand forecasting to route optimization, AI systems can predict and respond to supply chain needs in real time.

For example, AI can assess weather patterns, traffic conditions, and order trends to determine the best delivery routes, reducing delays and improving transportation efficiency. Similarly, AI tools can analyze data across multiple touchpoints to identify potential bottlenecks or disruptions in the supply chain before they cause problems.

When combined with smart software in warehouses, AI creates a seamless flow of goods, ensuring products move quickly and efficiently through the supply chain.

What Role Does Automation Play in Modern Warehouses?

Automation is no longer just a buzzword; it is a key driver of success in today’s warehouses. From robotic picking systems to automated inventory tracking, automation plays a significant role in making warehouses smarter. But how does it specifically help businesses?

- Robotic Systems: Robots can now handle repetitive tasks such as picking, sorting, and packing, reducing the need for manual labor. These systems work around the clock, ensuring a consistent and fast pace of operations.

- Automated Storage and Retrieval Systems (ASRS): These systems optimize the storage of goods by using robotics to retrieve items and bring them to the packing area. This reduces the need for human workers to navigate large spaces, improving both safety and productivity.

- Drones: In some advanced warehouses, drones are used to scan shelves and verify inventory. This provides real-time data and alerts warehouse managers about discrepancies, allowing for quick corrective actions.

By integrating these automated systems, warehouses can streamline their operations, improve safety, and reduce costs, making them a key component of any successful supply chain.

How Does AI Impact Inventory Management?

Effective inventory management is crucial to a warehouse’s success. Thanks to smart software, AI can now predict demand patterns and manage inventory levels with unparalleled precision. So, how does AI improve inventory management?

- Demand Forecasting: AI-driven systems analyze historical data to predict future demand trends. This allows warehouses to optimize stock levels, reducing the risk of overstocking or running out of popular items.

- Real-Time Tracking: With RFID and IoT devices integrated with AI systems, inventory is tracked in real time. This ensures that businesses have an accurate picture of their stock levels at any given moment.

- Stock Optimization: AI can analyze usage trends and automatically reorder products when inventory levels dip below a certain threshold. This means businesses can avoid costly delays due to stockouts.

Incorporating these features not only saves businesses time but also ensures a smoother flow of goods throughout the entire supply chain.

How Does Data-Driven Decision Making Lead to Success?

The data collected by smart software and AI systems is invaluable for making informed decisions. Warehouses now generate massive amounts of data related to every aspect of their operations. From inventory levels to delivery times, this data can be analyzed to identify trends and inefficiencies.

- Optimizing Operations: By analyzing the data, businesses can identify areas where they can improve operational efficiency. For instance, they may discover that certain warehouse zones are consistently slower due to equipment malfunctions or underutilization. With this knowledge, they can make targeted changes to optimize these processes.

- Better Forecasting: Data-driven decisions allow businesses to forecast future demand more accurately, helping them prepare for fluctuations in the market.

Ultimately, using data analytics to guide decision-making is one of the most powerful tools for ensuring continued supply chain success.

Conclusion: Is the Future of Warehousing Here to Stay?

The future of warehousing is already upon us, and businesses that adopt smart software and AI technologies today are positioning themselves for success tomorrow. By improving efficiency, reducing costs, and enhancing decision-making, these technologies are transforming the way warehouses operate.

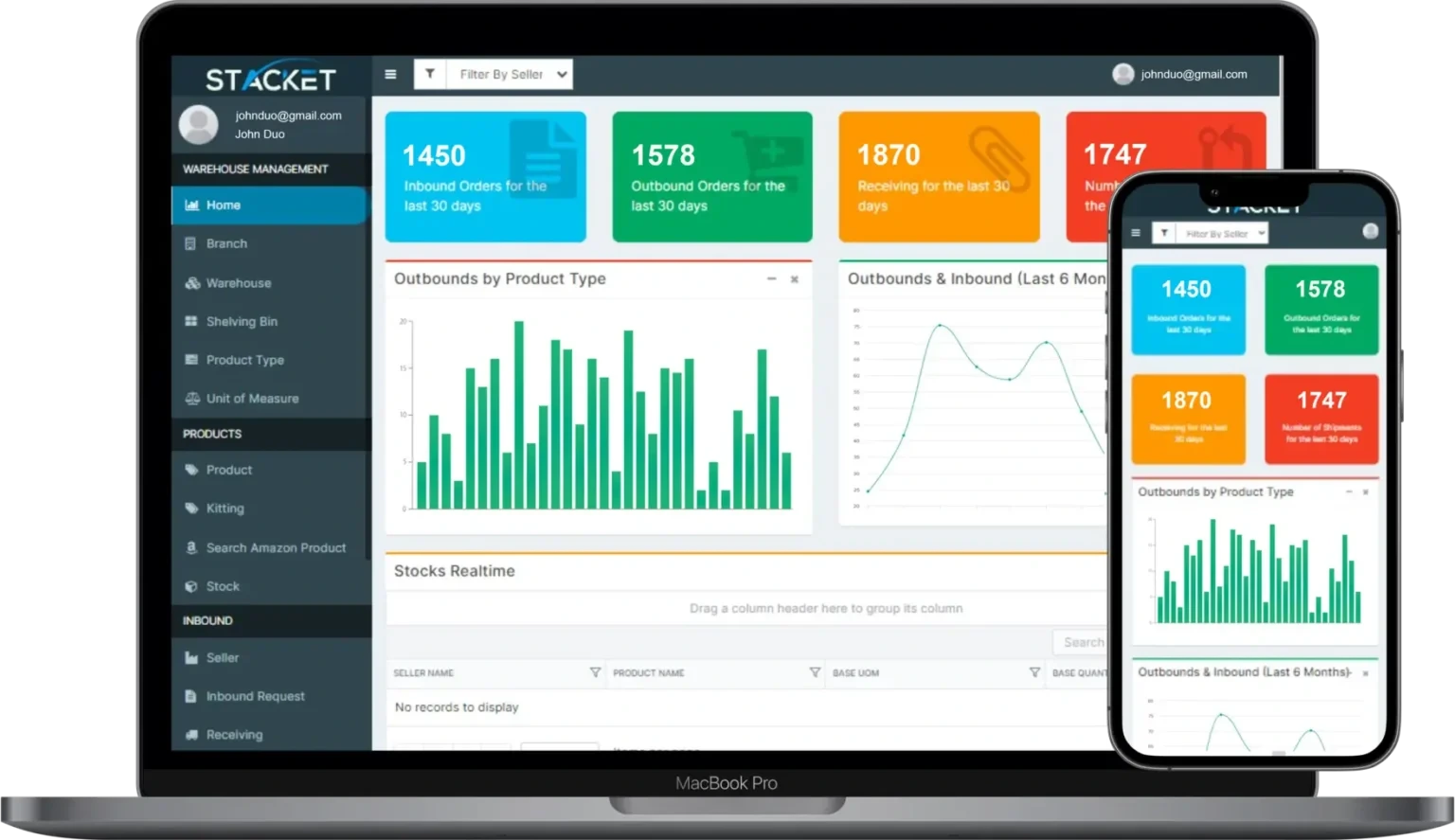

At StacketPro, we specialize in providing cutting-edge software solutions that can help businesses optimize their warehouses and achieve supply chain success. Whether you’re looking to automate your operations, improve inventory management, or enhance customer satisfaction, the future is bright for those who embrace AI-driven technologies.

Let us help you make your warehouse smarter, faster, and more efficient with smart software that transforms your business. The future of warehousing is here—are you ready to take the next step?